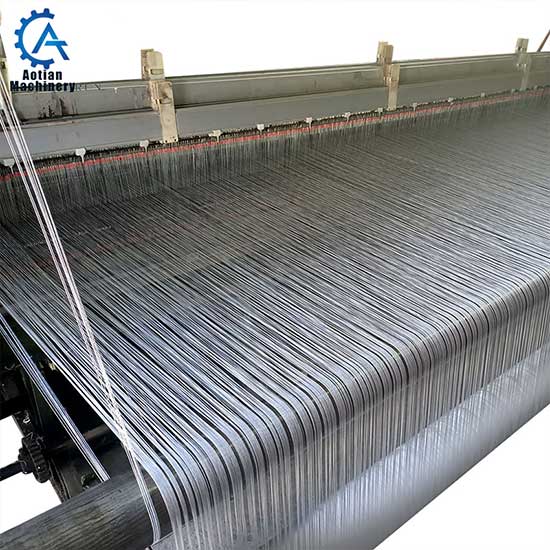

Name: Press Felt

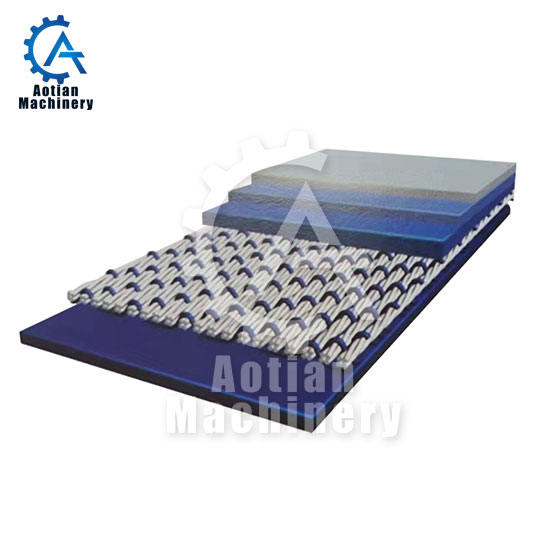

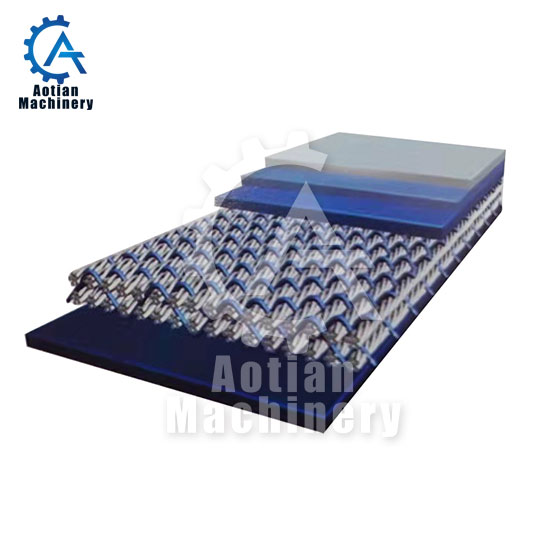

The use position of the pressing section: Top felt,Bottom felt

Material: Main is raw material chemical fiber

Thickness [mm]: 3.4

Permeability[cfm]: 75

Felt Weight[g/m2]: 1250

| Position | Press felt | Type | BOM Laminated1+1 | Size | 4.25*16.35*1250 | ||

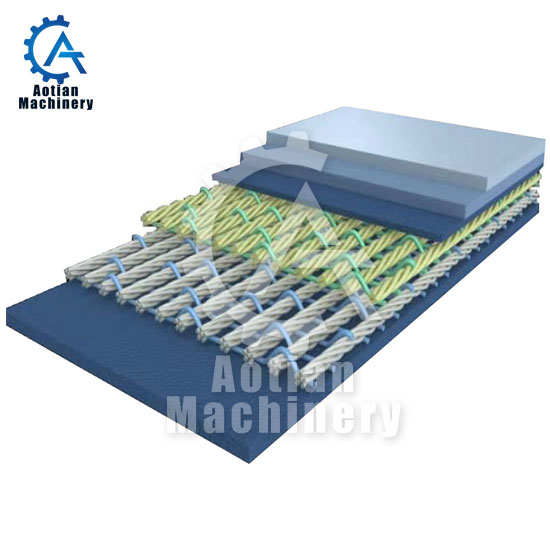

| Quality Recommendation 1:Endless felt afford uniform tension and stable mesh、twill weave extremely good anti-compact ability 2:Lapping batt layer by layer, it can preventive to pulp penetration and ensure to keep the flexibility of felt. 3:Reversed side has two layers of batt in order to improve the wear resistance. | Mesh | Pattern | 1/3 | 1/3 | |||

| Weight | 310 | 260 | |||||

| MD Yarn1 | 0.2*6 | 0.2*4 | |||||

| Weft | 0.4*1 | 0.35*1 | |||||

| Batt | Surface | 22D 2*110 | |||||

| Subface | 33D 2*133 | ||||||

| Innerface | 44D 2*100 | ||||||

| Thickness [mm] | 3.4 | ||||||

| Permeability [cfm] | 75 | ||||||

| Felt Weight [g/m2] | 1250 | ||||||

| Felt Maintenance ①High pressure washing pressure 10-18kgf /cm2; ②Spray 2-kgf /cm2 at low pressure to reduce friction between felt and panel; ③Stop the machine to relax the felt tension and perform chemical cleaning; ④The vacuum degree of the return vacuum box is 0.04-0.05MPa. | |||||||

If you have any questions, please fill in the following information, we will reply you as soon as possible