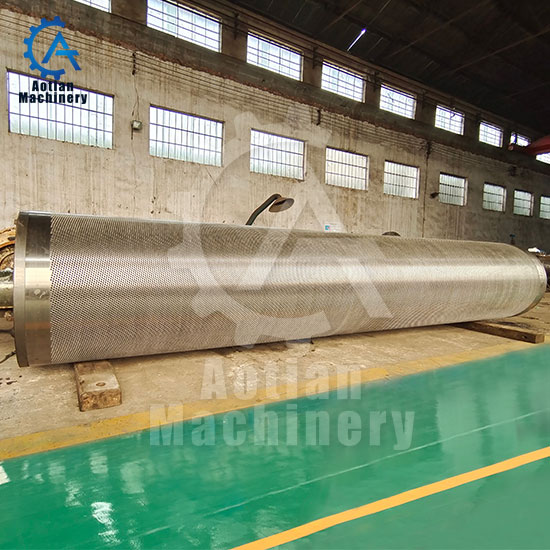

Name: Combination roller

Working face: 1600-6200mm

Working speed: Customized according to customer requirements GSM

Center distance: 1650-7000mm

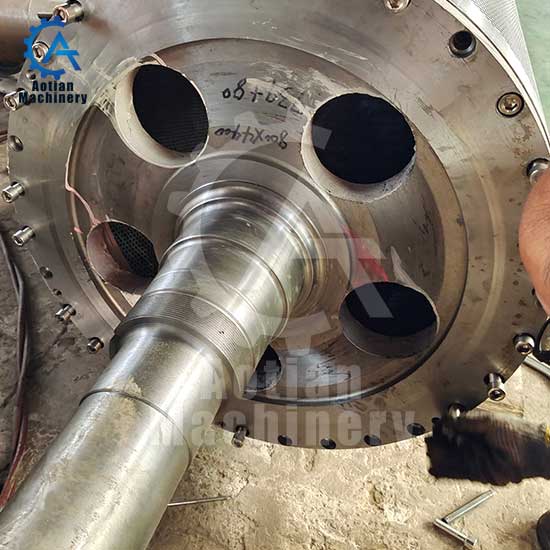

Diameter: 650-1000mm

Hole size: 5.5mm-9mm

Shell material: 0Cr17 or 304SS

| Working face | 1600-6200mm |

| Diameter | 650-1000mm |

| Center distance | 1650-7000mm |

| Working speed | Customized according to customer requirements |

| Dynamic balance speed | Set according to customer working speed |

| Shell material | 0Cr17 or 304SS |

| Hole size | 5.5mm-9mm |

| Can be completely customized according to customer requirements | |

If you have any questions, please fill in the following information, we will reply you as soon as possible