Imitate stone roller

It is mixed with special grade synthetic rubber material and nano-grade filling material. It has good paper peeling performance and unconventional wear resistance. It can be used with a scraper and can meet the harsh application environment of high line pressure. The imitation stone rubber roller has low quality, high hardness, good paper making and release performance, impact resistance, abrasion resistance, acid and alkali corrosion resistance and high production efficiency. It is an ideal substitute for natural stone roller and has good social and economic benefits.

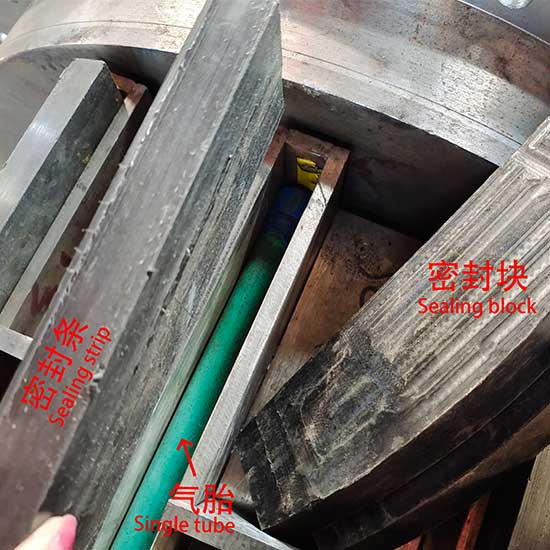

Structure Principle

The imitation stone rubber roller is composed of a metal roller core and a rubber coating (including a surface adhesive layer and an adhesive layer). In order to satisfy the imitation stone rubber roller with high hardness, good paper making and release properties, pressure resistance, abrasion resistance, and aging resistance , Heat resistance, acid and alkali corrosion resistance and other performance requirements, the surface glue adopts NR/BR/high styrene resin and the system as the main material, adopts glass hollow beads/zinc oxide/superfine aluminum silicate/white carbon black/methyl Magnesium acrylate system is used as reinforcement system.

Read More